Our cardboard boxes (or cartons) are made from corrugated sheets in either single wall boxes or double wall boxes. We have put together this packaging guide to help you identify exactly what you need so you’re not paying too much for shipping your products.

For smaller e-commerce businesses and hobbyists who ship out their products through the post, finding the correct sized Royal Mail box can be crucial. Most UK mail is handled by Royal Mail, and they have various price brackets for different packaging sizes.

We have put together this handy guide on standard box sizes to help you understand what shipping your products may cost when sending them first class.

If you sell products online, it is important to understand the pricing breaks and have packaging that will maximise your profits. A parcel only needs to go a few millimetres over the maximum allowed for it to affect the shipping costs considerably.

If you’re dispatching 20 2kg parcels each working day on a first class service using the ‘medium parcel’ size instead of the ‘small parcel’ size could cost you an extra £69 per day, or £365 per week. Do this for a year and the cost increases to just short of a staggering £19,000. Showing just how important understanding shipping box sizes can be to businesses big and small.

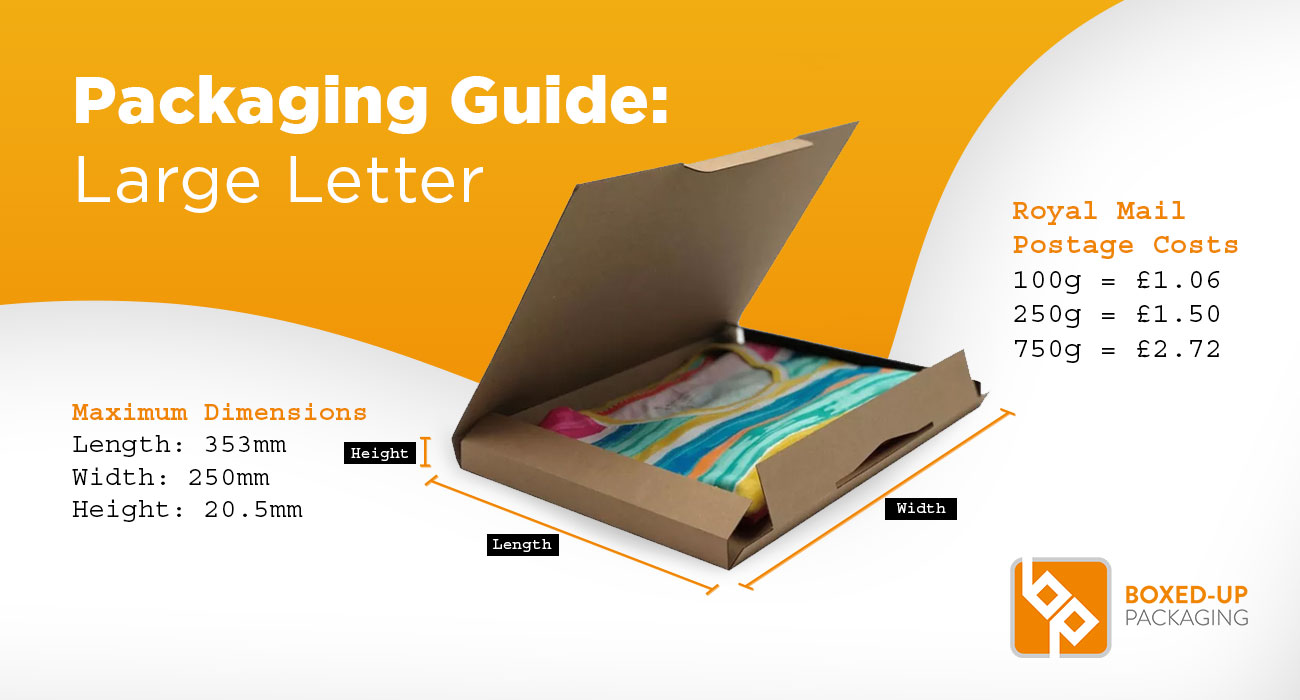

Large letter postal boxes are designed to fit through most UK letterboxes making it an ideal shipping box for smaller items.

| Large Letter Maximum Dimensions | Large Letter Royal Mail Postage Costs | ||

| Length | 353mm | 100g | £1.06 |

| Width | 250mm | 250g | £1.50 |

| Height | 20.5mm | 750g | £2.72 |

View the full large letter packaging guide for further information.

We supply 2 boxes that comply with Royal Mail's Large Letter standards, these are:

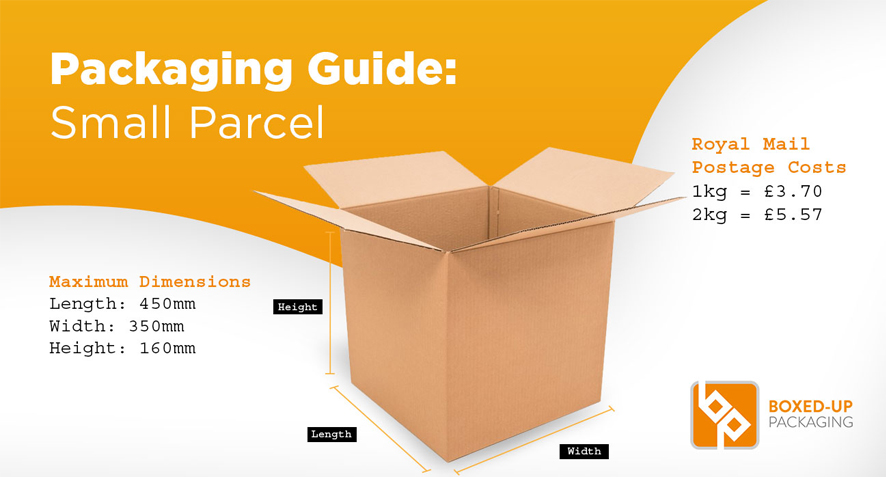

| Small Parcel Maximum Dimensions | Small Parcel Royal Mail Postage Costs | ||

| Length | 450mm | 1kg | £3.70 |

| Width | 350mm | 2kg | £5.57 |

| Height | 160mm | ||

4x4x4, 5x5x2.5, 5x5x5, 6x4x3, 6x4x4, 6x5x4, 6x6x6, 7x5x2.5, 7x5x5

8x6x4, 8x6x6, 9x6x3, 9x6x6, 9x7x3, 10x10x6, 12x7x3, 12x9x2,

12x9x4, 12x9x6, 17x13x6 8x6x2, 9x6x2

Both single wall and double wall options are available to provide adequate protection. Check out the full small parcel packaging guide for more information and packaging tips.

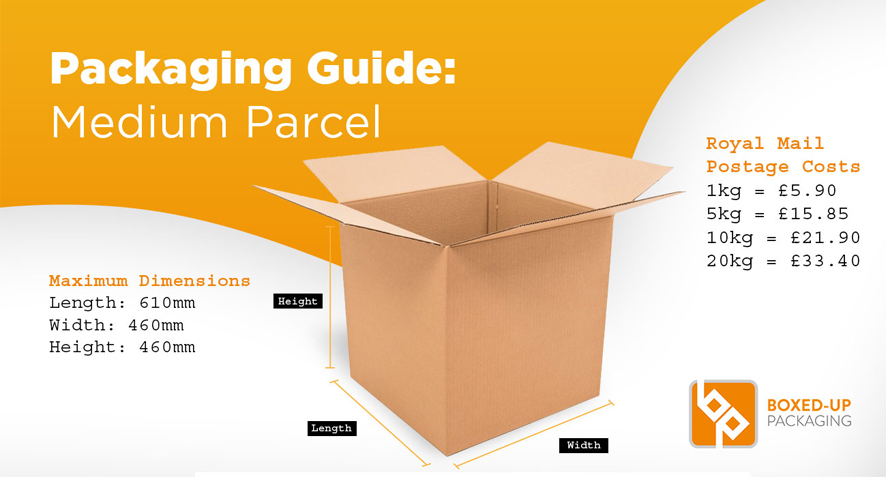

| Medium Parcel Maximum Dimensions | Medium Parcel Royal Mail Postage Costs | ||

| Length | 610mm | 1kg | £5.90 |

| Width | 460mm | 5kg | £15.85 |

| Height | 460mm | 10kg | £21.90 |

| 20kg | £33.40 | ||

8x8x8, 10x10x10, 12x9x9, 18x12x12, 18x13x13 4x4x13, 4x4x8, 7x7x5, 8x8x6, 9x9x6,

For heavier products, it is recommended that a double wall shipping box is used for extra strength. Check out the full medium parcel packaging guide for more information and packaging tips.

If you're looking for custom packaging, our sister company Belmont Packaging can help. For more packaging information, read on!

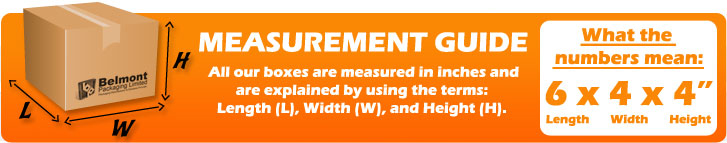

Standard corrugated boxes are always measured in the same order(with the box opening at the top);

The box dimensions, stated by a supplier, refer to the internal (usable) dimensions of the carton.

We supply a range of various sized boxes and understand this can be daunting when you are unsure which size box you need. In order to find the right box for your needs, you will need to determine how large your product(s) will be that you wish to house in the same box.

Firstly, we suggest measuring your goods. It is good practice to measure your goods in the same way as manufacturers; length x width x height. This will make it easier for you when determining and picking a stock box size. It's also perhaps a good idea to think of other layouts of your products, as this can bring up other stock box options which may be suitable.

When choosing your box remember that bubble wrap, foam chips and other protective packaging material will add to the space needed. They are also great void fillers if your box is slightly too large. It is best to select a box that is slightly larger in all 3 dimensions to allow room for the protective padding.

Ideally, the best packaged goods are those which sit snugly inside the box, meaning the minimal movement of your goods during transit.

A standard corrugated board is made up of two main components; linear board and corrugated fluted paper. The sheet of fluted paper is sandwiched between the outside and inner liner which is then glued to the flat liner paper from scratch.

When searching for a corrugated case you will generally see a description of the board as Z125KT - this is a shorthand way of writing the board grade, paper weight and fluting size. Here’s what the breakdown means:

Z - Fluting size

125 - Paper weight

KT - Kraft/ test paper (outer/ inner liner)

Most boxes are a combination of Kraft and Test paper. Kraft paper is made of virgin fibres using softwoods from sustainable forests. This is the most commonly used paper outside of liner due to its nature. Test paper is mostly made up of recycled papers, giving it a mottled effect and is the most common inner liner used when creating corrugated packaging.

Single wall boxes are constructed utilising one layer of fluting. They are most commonly used for e-commerce shipping packaging, as they are a cheaper alternative to double-wall yet still provide an element of rigidity and cushioned protection required of a shipping box.

Single Wall boxes are reliant on the flute, to determine the properties of that case. For example, Z Flute combines lightweight with compression strength to withstand the rigours of shipping, stacking and consumer use, which is why we have chosen this fluting for our single wall cardboard boxes.

Double Wall (BC) boxes are constructed with two layers of fluting, generally in two types of flute sizes. The 5-ply construction provides a greater strength over the double wall, making them the perfect choice for heavier items or items which require a higher level of protection.

Double wall boxes have an increased rigidity over single wall, making them ideal for long term storage.

The difference is the thickness of the fluting relating to the strength of the box. A double wall is required for heavier and is more resistant to direct hits in transit. A single wall is ideal for e-commerce packaging due to the price and will protect lighter products without any issues, whereas, a double wall is ideal for heavier and more fragile products.

If you're an e-commerce business, the answer will likely be no. However, modern shopping trends have changed, and if you're a business looking to take the next step and offer a more personalised customer experience, custom packaging may be for you. Our sister company, Belmont Packaging, has put together a blog that will help you decide if branded packaging is for your business or not.

Good Sturdy Boxes We have been using Boxed Up for a few years now, and is an integral part of us meeting our customers' expectations. They offer a friendly and professional service. The only negative we have is that their new website has been 'coming s

The one of the best box supplier in the UK I have ordered boxes from Boxed Up many times. They have great prices, very quick response time, next day delivery. What else can I say: The one of the best box supplier in the UK, Thank you

I ordered 25 Boxes from Boxed Up Packaging . They acknowledged the order and kept me informed as the order was being processed and I got notifications from the delivery company at each stage. What a fantastic system. This is how business should be done. I